Prospecting for gold is an activity that has captured the imagination of man for thousands of years. There’s something about gold that grabs at our sense of adventure like nothing else in the natural world. The men and women who participated in the gold rushes of the 1800s left us with rich stories that are just as entertaining to read today as the day that they happened.

If you are the kind of person who loves the outdoors, craves adventure, and enjoys the sense of accomplishment that comes along with achieving difficult goals then gold prospecting is an activity that you should consider.

There are a lot of things to think about when starting to become a prospector. The first thing is to determine what your personal goals are. There are several different paths that you can take and each one will require different skills and knowledge.

Choose your path

Do you want to be a recreational prospector? That would mean prospecting as a hobby or pastime while still having another source of income. Recreational prospecting is a great hobby and very rewarding. As a recreational prospector you may or may not need to own a claim and the investments in equipment and training are minimal.

If you aspire to become a small-scale miner you’re going to have to invest a lot more time and money into your endeavors. You’ll need to hold your own claim and will require substantially more equipment than a recreational prospector.

Full-scale commercial miners are a whole different story. You’ll require advanced knowledge of gold deposits, exploration, sampling, and mining techniques as well as heavy investments in mining property and equipment.

In addition to the scale of mining activities that you plan to engage in you’ll have to think about what type of prospecting you want to do. There are two general types of gold prospecting Hard Rock and Placer.

Placer gold is the type that is deposited in river gravels and ancient stream beds. Hard rock gold is located in its original source, in actual rock. The prospecting techniques and methods used for placer and hard rock are totally different with very little overlap. There’s nothing wrong with wanting to explore for both types of gold.

Once you’ve set your goals you’ll be better positioned to set yourself up to reach them. It’s pretty difficult to start from scratch and become a full-scale commercial miner in your first year but that hasn’t stopped people from trying. If you are considering that path make sure that you have some people supporting you with legitimate mining and exploration experience.

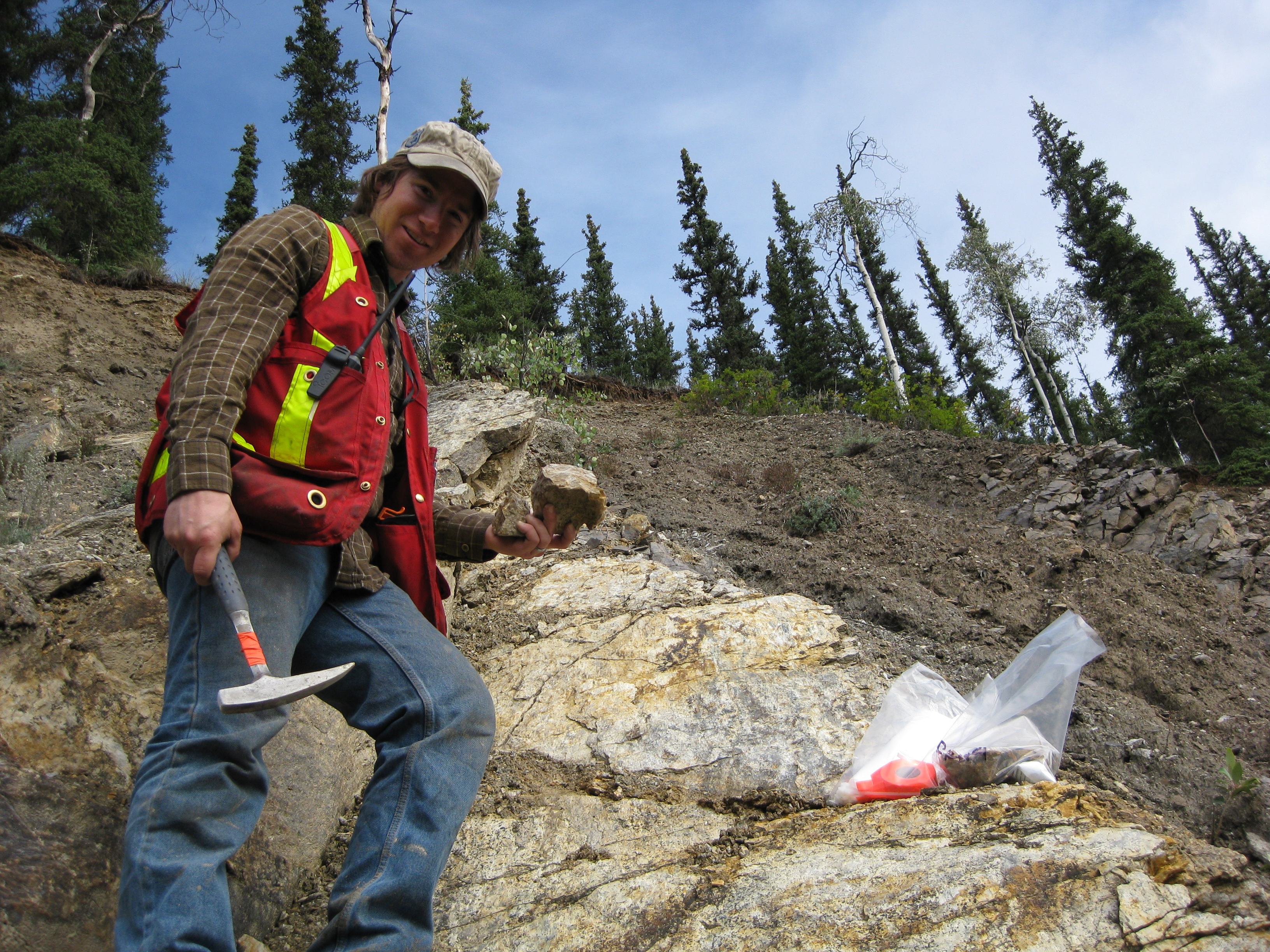

Learn prospecting techniques

Different types of gold deposits require different techniques to find them. As a fledgling prospector, you won’t become skilled at all aspects of gold exploration right away. You’ll have to determine what type of prospecting you want to focus on.

To get started you’ll need to learn some basic geology and an understanding of where gold is likely to be found. You don’t have to become a geologist but it will be helpful to understand a few of the different rock types and environments where gold is commonly found in your area. Placer gold is found in creeks and ancient river channels while hard rock gold sources can occur pretty much anywhere in the right kinds of rock.

You’ll want to learn the difference between igneous, sedimentary, and metamorphic rocks. You’ll want to be familiar with minerals that occur in the same environment as gold such as quartz, pyrite, chalcopyrite, and mica. It’s important to be able to tell the difference between fool’s gold and real gold.

For hard rock prospecting, you’ll want to be able to recognize the types of environments where gold deposits form. Some common types are epithermal, porphyry, and volcanic massive sulfide. That all might sound new to you now but through research and experience, you’ll learn to recognize the signs of these different environments.

Placer gold and hard rock gold start out the same but end up being collected in different locations. Placer gold is just in-situ gold that has been eroded and concentrated in a creek or river environment. That being said, placer deposits don’t always point towards hard rock deposits and the opposite is also true.

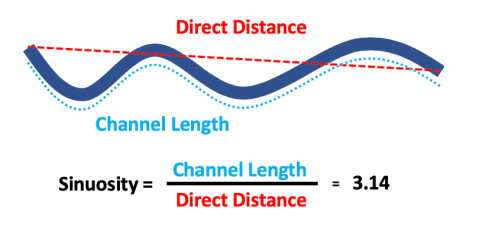

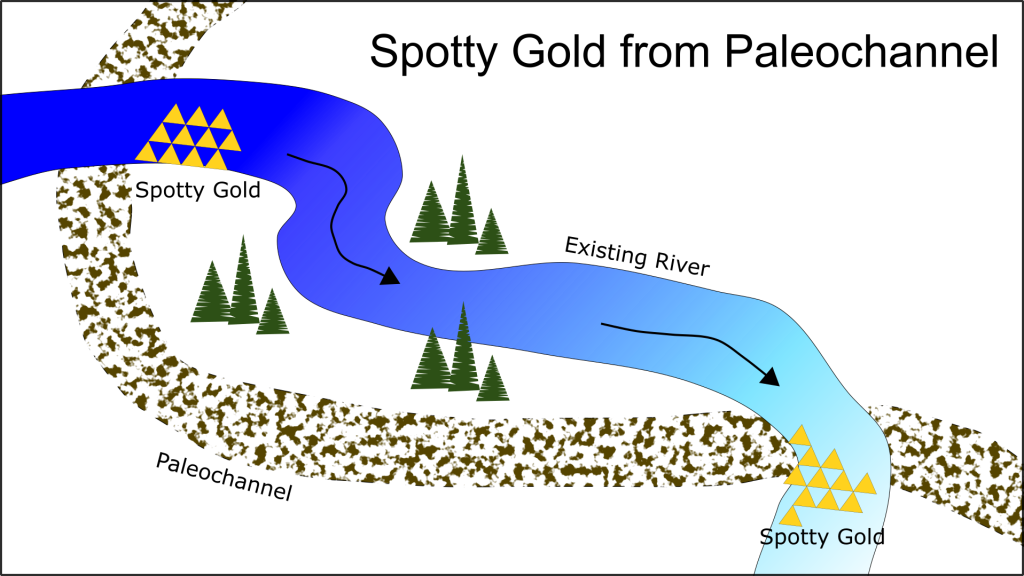

In placer exploration one of the most important things to understand is how to read a river. That means being able to understand which parts of a creek are likely to contain concentrations of gold. Placer gold is not distributed evenly, instead, it collects in certain parts of a stream while other parts have little to no gold.

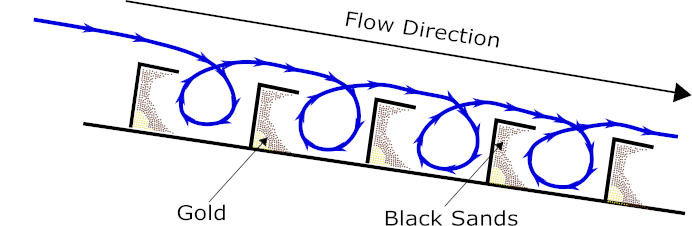

The density difference between gold, water, and other minerals is a key component of placer prospecting. Since gold is very dense it takes a lot of energy to move it, when the water loses energy the gold will stay put. Basically, gold will accumulate in sections of the creek where the water velocity slows down. For example on the inside bends where a point bar is forming, on the downstream side of obstructions in the creek, or on riffles or old channels.

You’ll need to recognize the different types of placer deposits. Not all placer gold is found in streams.

- Flood Gold is found in the upper gravels of a creek or river that actively move during floods. This gold tends to be small in size and can change from year to year. Flood gold can be found right on the surface of gravel bars in many cases.

- Streambed Placer deposits are located within a stream or river channel but in stationary gravels that don’t move with seasonal floods. Streambed deposits tend to have larger gold but require more work to produce. When prospecting these deposits get as close to bedrock as you can as gold will sink to the bottom over time.

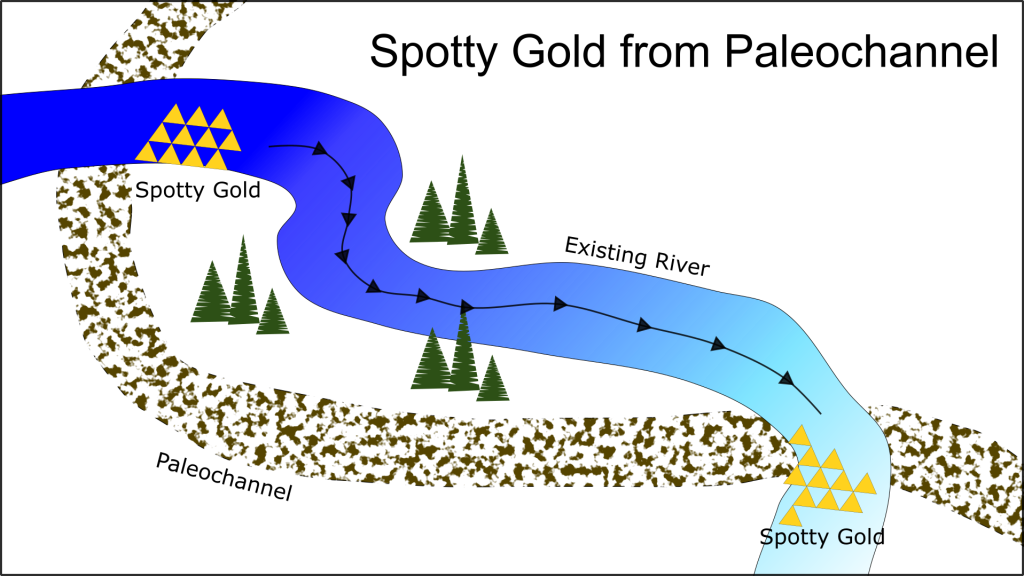

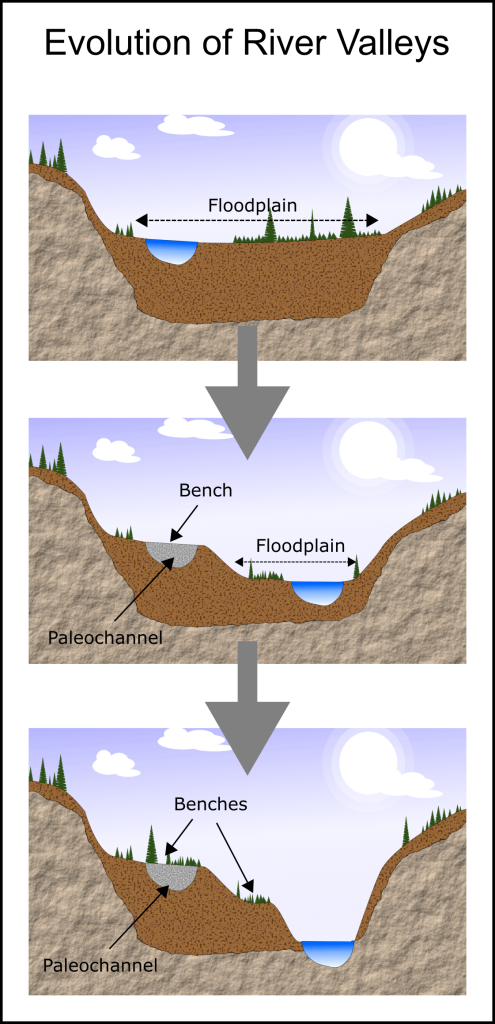

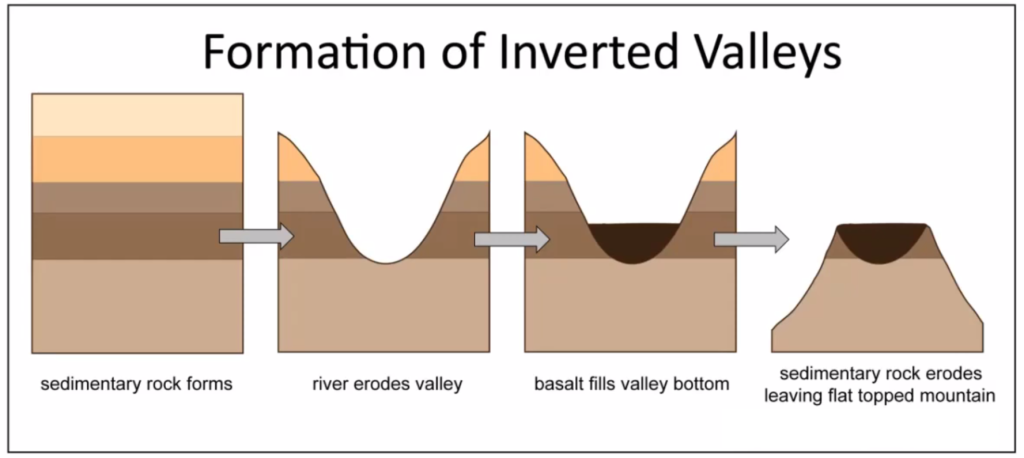

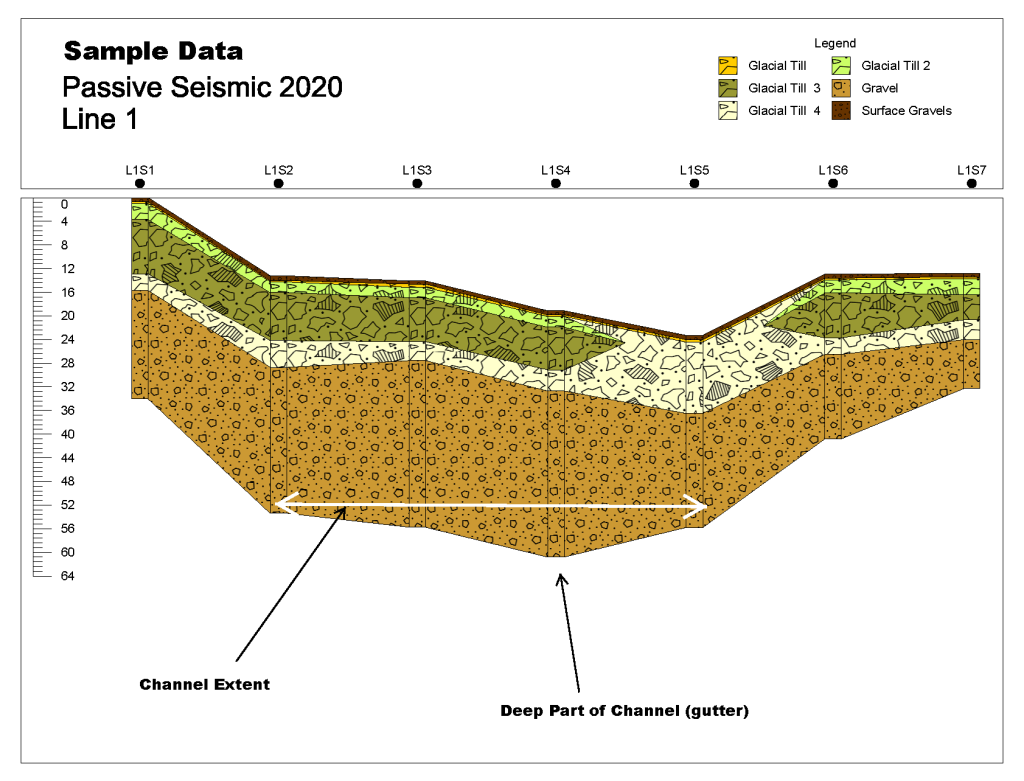

- Bench Placers and Ancient Channels are remnants of old rivers that have changed course. They are basically streambed placers but the river is no longer running with water. Benches can be high above the current river and ancient channels can be in a totally different course than the river today. These are difficult to prospect but locating one of these deposits could bring you lots and lots of gold. More info on that here: Paleochannel Hunting Guide

- Residual and Eluvial Placers are placer deposits that form near a hard rock source. They are formed by erosion as gold-bearing rock breaks free from its source. Gold can accumulate in the hillside in pockets. These deposits can be very rich but tend to be small in size. Pocket hunting can be lucrative for a small miner though.

- Beach Placers form by concentrating placer gold due to the wave action of a beach instead of the flow of a river. A famous example of this is the deposit in Nome, Alaska which is featured in the TV reality show “Bering Sea Gold”.

Once you’re able to recognize places where gold is likely to accumulate you’ll need to test the gravels. There is one fundamental skill that is used at every stage of placer prospecting and that is gold panning. You’ll have to spend the time to become good at gold panning. There are numerous devices available that are marketed to make up for lack of gold panning skill. No tool is more important to a gold prospector than his trusty gold pan!

Gold panning, like all placer methods, is based on the density difference of gold vs water, gravel, and black sands. When suspended in water gold will sink to the bottom of the pan. There are two steps to gold panning, agitating the material and washing away the less dense sands. As you’re panning you’ll alternate between these two steps, agitate and wash. As you’re agitating the material you’re allowing the gold to sink to the bottom of the pan, then you want to keep the gold in the bottom while you wash away the lighter material. Eventually, you’ll be left with only gold and nothing else.

Just like any skill it takes time to master. The best way to learn is to start out with lead shot. Try different sizes of shotgun pellets or BBs and mix them with gravel to practice. Once you’re able to separate the shot from the gravel you’ll be ready to try it for real.

You don’t need a lot of tools to start out. Lots of people go on a buying spree when they get started in prospecting. Don’t do that. All those extra gimmicks aren’t going to help you find more gold. Especially things like metal detectors and panning aids.

In addition to a gold pan, you’ll want a ½” or ¼” screen and a snuffer bottle. That’s all you need. The screen helps remove the larger pebbles which makes panning easier and faster. A snuffer bottle is a small plastic bottle that helps you keep your gold. It functions like a turkey baster, you squeeze it and use the bottle to suck up gold out of your pan for safekeeping.

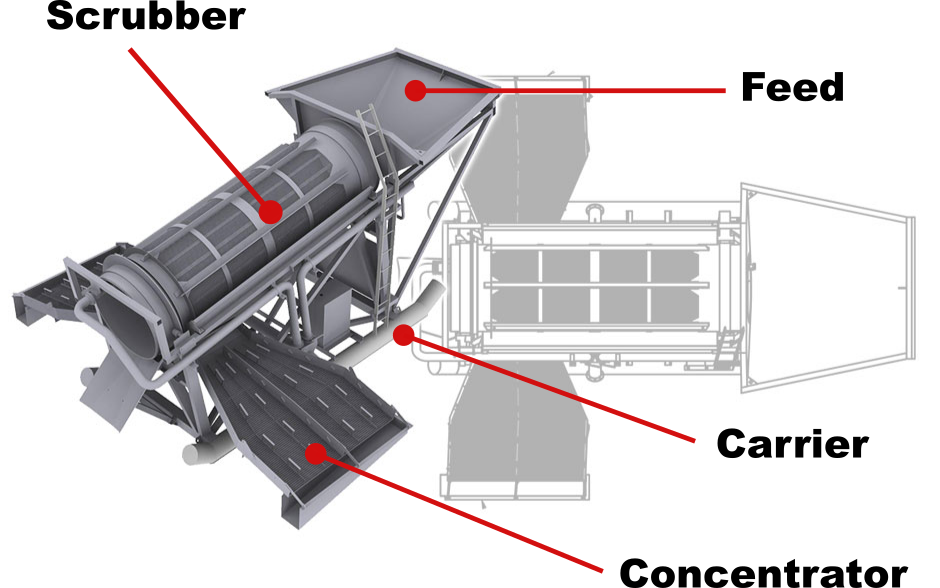

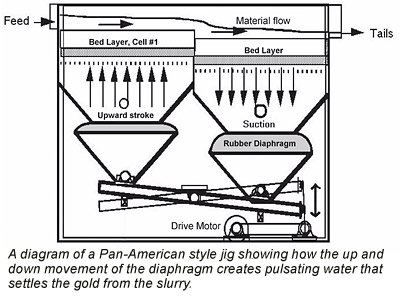

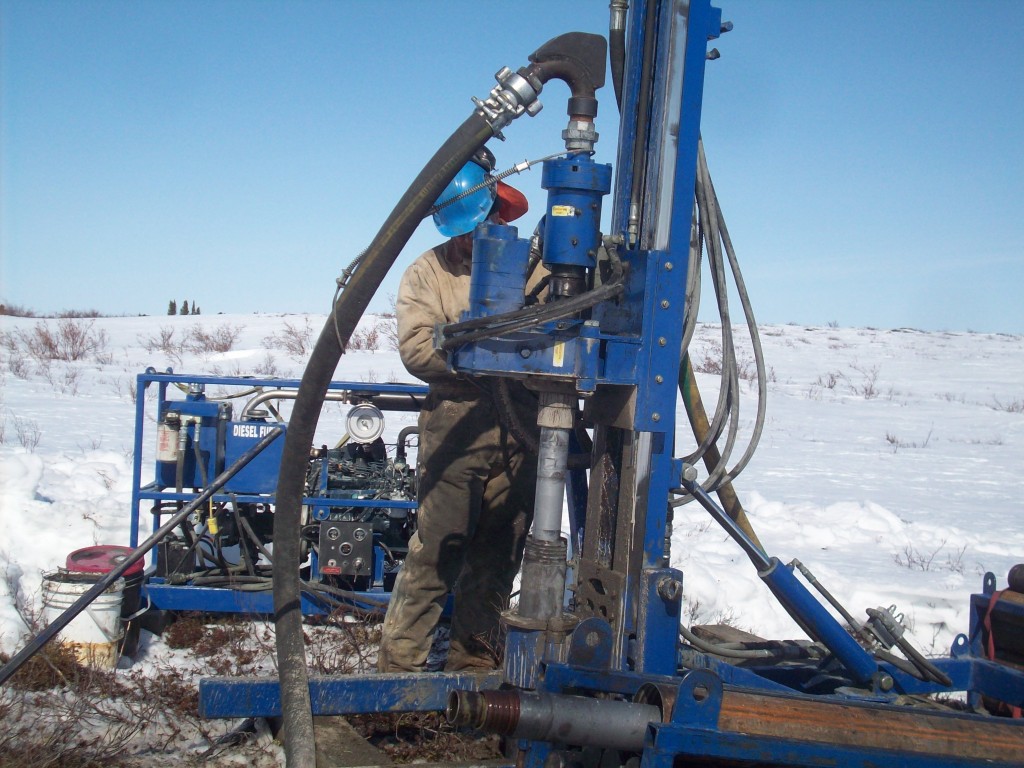

As you advance in your prospecting career you’ll find the need for additional tools. Gold pans are excellent for testing gravels and separating concentrates but sooner or later you’ll want to run larger samples and produce a bit of gold. To run larger samples you’ll need a device that can concentrate gold at a higher rate.

A sluice or highbanker is the next logical step. A sluice is a tray set at an angle with riffles that collect dense material (ie. gold). A highbanker is a portable machine with a sluice and a hopper that allows for concentrating larger amounts of material, usually between ¼ to 2 yards per hour. A high banker is the largest machine that you can run in BC without a permit, more on that below.

There are much larger wash plants available for larger-scale testing and full-scale mining.

When it comes to larger-scale mining you’ll need to learn about exploration, sampling, and mining on a larger scale. Each of those steps requires a lot of detailed knowledge, give us a call when you get to that stage and we’ll help you out.

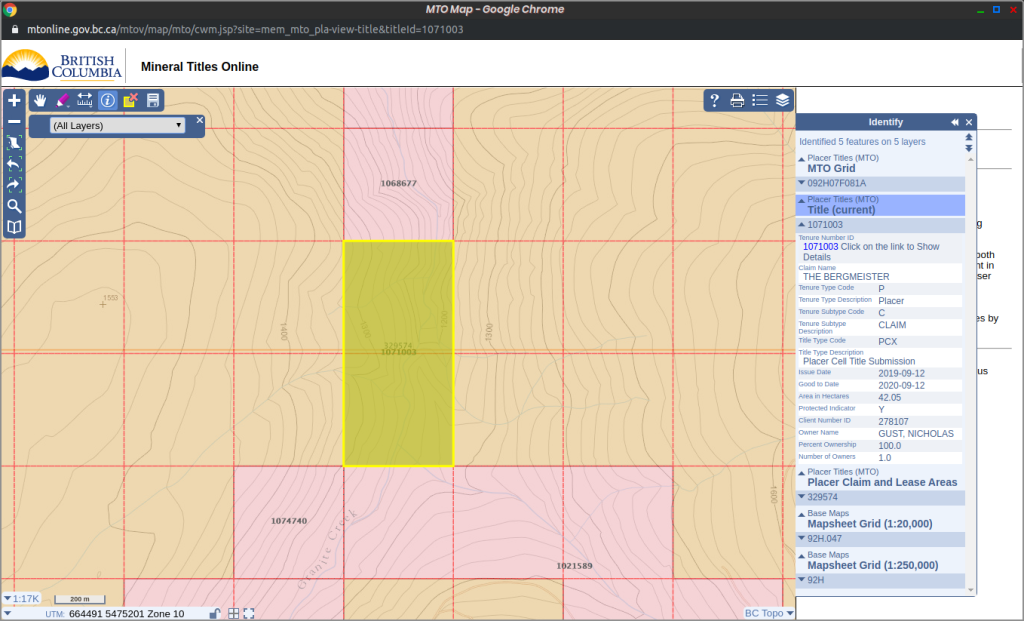

Stake a Claim

Once you’ve made a discovery it’s time to stake a claim. There are a lot of things to consider when deciding which claim to stake. You’ll want to consider things like location, accessibility, price, type of deposit, and several other factors before you commit to a piece of ground. You’ll also need to consider the licensing and regulations.

In British Columbia, it is necessary to hold a Free Miner’s Certificate in order to hold a claim. This certificate provides certain rights such as access to mineral lands and to tenure ownership. The history of the FMC actually dates back to medieval Europe.

In order to obtain an FMC in BC it is necessary to visit a Front Counter office in person to verify your ID. The government website can guide you through the process.

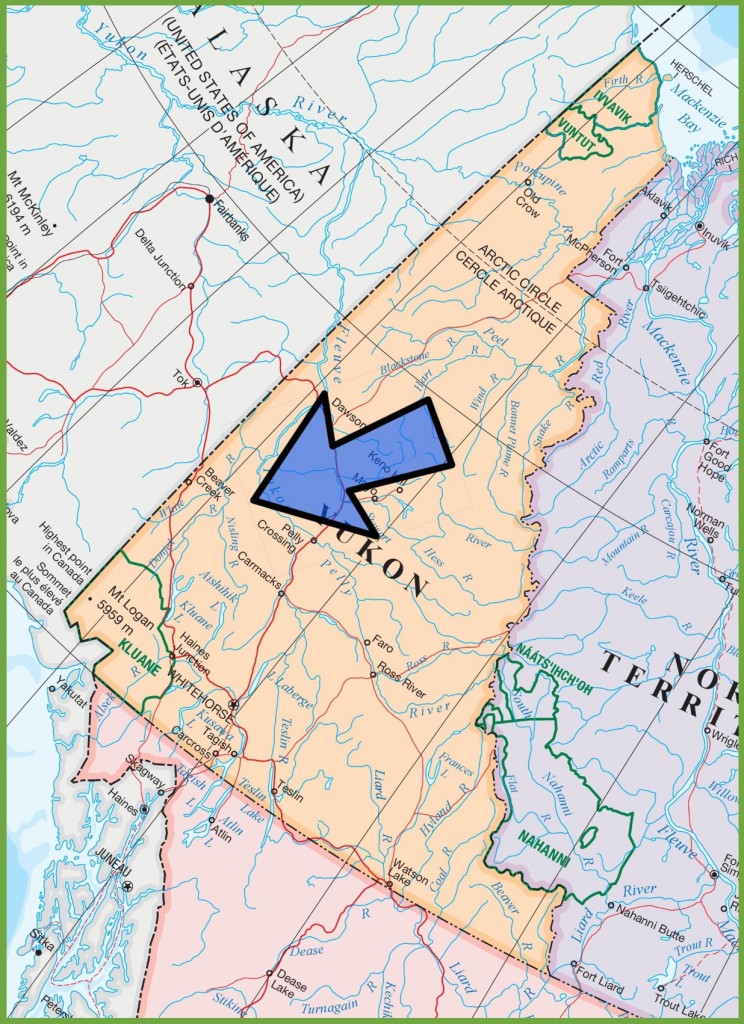

You’ll have to decide if it’s beneficial for you to stake a claim yourself or to buy one from somebody else. The cost to stake a claim is quite low, in BC it costs about $100 for each 500m x 500m cell in staking fees. This is done with BC’s online staking system. In other jurisdictions such as the Yukon, physical claim posts are still used. There is a lot of debate about which system is better but that is beyond the scope of this article.

Buying a claim from someone else is much more expensive but if that person has already done some of the exploration work it could be worthwhile. Be extremely cautious of people advertising claims with good gold on them. Since the early days of the gold rushes in the 1800s speculation and deception have been part of this business. Mark Twain famously defined a gold mine as “A hole in the ground with a liar at the top”. Today is no exception.

If you are considering buying a claim from someone else do your due diligence first. That means doing your own testing on site. Test enough so that you’re confident in the gold grades being advertised. If you aren’t confident in your ability to do that then you’re not ready to buy a claim.

- Location: The location of a claim is fundamental to whether it will be successful or not. First and most importantly it must have gold on it. After all, you can’t mine gold if it isn’t there. As mentioned above you should do significant research and test an area prior to staking it. Secondly, you need the claim to be in a location that you can get to on a regular basis. If it’s located far away from your home and you can only get there once a year how will you be able to work it?

- Access: Aside from the gold grades you’ll need access to the property. You’ll have to decide what kind of access is necessary. If you want to be bringing in equipment you’ll need some kind of road access. Some newly discovered areas don’t have roads but you’ll need to decide how adventurous you want to get and how much development work you’re willing to do on your own. You’ll also want to determine the access to water and if you can get down to the creek or not. Is the claim in a canyon, or on top of a mountain?

- Type of Deposit: as we discussed above there are different types of placer deposits. An area that you are considering claiming could have a creek, or it could be on a high bench with no water. It could be a beach placer or even high up on a mountain. All of these areas could host a viable gold deposit but you’ll have to decide if your skills and ambition are a match for the task at hand.

- History: the mining history in the area is also important. You don’t want to buy a claim that’s already been mined out. It’s important to make sure that there’s still some gold left for you. There are scenarios where historical miners make mistakes or had poor prospecting techniques and left lots of gold behind. Sometimes that can be due to superstitions or insufficient funds. It’s also important to not get caught up in urban legends or miner’s tales about the area.

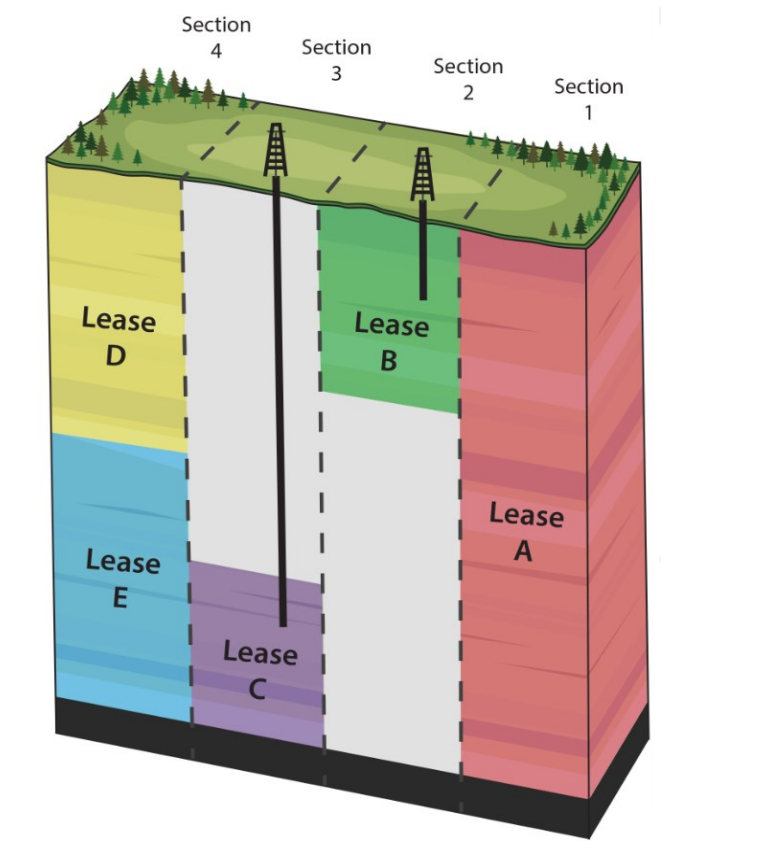

- Other Land Owners: a mineral or placer claim gives you the rights to the hard rock or placer minerals within the boundaries of your claim. It does not give you ownership of the land. Someone else could own private property in the same location, other parties could have the forestry rights, traplines, or there could be things like a power line or pipeline right of ways, gravel pits or indigenous land. There are also provincial parks and other types of land ownership such as legacy claims and crown-granted claims to look out for. As a claim owner you have certain rights to access and develop your claim (even if it’s on private property in many cases) but the less conflict you have the better.

Ownership of a claim gives you certain privileges but it also comes with responsibilities. A claim will require upkeep in the form of assessment work or payments in lieu. You’ll also need permits for advanced work and mining which require a lengthy application process and first nations consultation in most cases. Spend the time to properly research and test a claim before you take the plunge, especially if you’re considering spending a lot of money on it.

Learn the Regulations

No matter what scale of gold prospecting you are going to engage in you’ll have to learn the rules and regulations. Now that’s easier said than done. In most jurisdictions, the rules are not readily available, especially in British Columbia. The major rules are usually somewhat easy to find but they are always ripe with exceptions and open to interpretation. Unfortunately, the mining regulations in BC are based on a patchwork of laws and there is no manual or anything that clearly summarizes the rules. Just like any law though ignorance of the law is no excuse for breaking it.

In BC, the rules regarding mining claims and land access are covered by the Mineral Tenure Act. You can access the regulations here: Mineral Tenure Act

The BC Ministry of Mines (or The Ministry of Energy, Mines, and Low Carbon Innovation if you want to use their full name) has put out a good summary of the rules for small-scale mining without a Mines Act Permit called Bulletin #38. You can access that document here: Permissible Activities without a Mines Act Permit

Other acts that regulate mining activities are the Mines Act, the Mining Right of Way Act and the Water Sustainability Act. The MTO website has links to the actual legislation behind those acts: BC Mining Legistlation

Small scale mining without heavy equipment is permitted in BC under the conditions in Bulletin #38. Larger work programs require permits from the Ministry of Mines and are subject to additional regulations.

There is no guidebook to the BC mining laws. It would be nice if the government could put together a book as they have for studying for your driver’s license. Unfortunately no such document exists. The Atlin Placer Miner’s Association put together a document called the Atlin Placer Mining Best Management Practices Guidebook, which was an attempt to create a guidebook.

This article is a brief overview of how to get started in placer mining. This is by no means a comprehensive guide. Each of the points mentioned in the article should be followed up on. Hopefully we answered some of your questions though.

There’s always more to learn and a good prospector will always be learning. Even experts in the field welcome the opportunity to learn a little bit more. The best advice we can give is to be patient, pay attention and hopefully you can find an experienced prospector to work with. The best way to learn is to work with someone who already has the knowledge.

Happy hunting!